We live in uncertain times what with Brexit, unstable global affairs and snap UK elections, all creating market situations that may inspire businesses to err on the side of caution. According to Allan Scrafton, head of marketing for forecourt and asset resilience experts, Adler & Allan, maintaining what you have will help any organisation weather the storm of shaky markets; while ensuring pollution is prevented and downtime is avoided, are key to our sector, whatever the forces at play.

"Brexit and how it is implemented is still causing uncertainty across the board." he says. "While (so far) the fallout from the momentous EU Referendum has been less impactful than predicted, until we actually ’leave’ it is hard to gauge the full effect.

"No one can truly see into the future, so the best approach for any business with an eye to long-term success is to make sure that the assets they have are protected, safe and fit for purpose, which is of particular importance to the forecourt sector where pollution is a very real threat.

"Failing assets will cost in terms of expensive replacements, downtime and potential disaster, which could see an organisation’s reputation damaged, not to mention risk the environment. Maintaining and improving essential equipment will enhance useful life and therefore stabilise value, preventing wastage as well as cutting costs. The best approach to asset resilience should be predictive, avoiding breakdown altogether, and allowing budgets to remain stable, rather than having to shell out off-plan amounts should things go wrong."

And, with forecourts so important to the running of the country, Scrafton says the knock-on effect of downtime can be extremely disruptive: "We all remember the long queues as a result of fuel protests at the beginning of the millennium.

"To that end, the importance of asset resilience in our sector goes beyond the profit and losses of individual businesses, as it potentially affects the bottom line of any organisation reliant on road transport (pretty much everybody!)."

Assess, monitor and improve

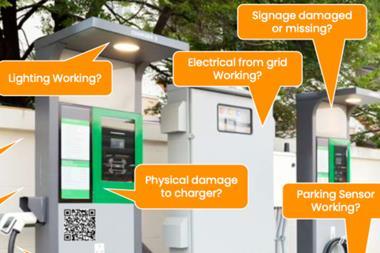

The first step in a programme of asset resilience should be assessment, stresses Scrafton: "What state are your assets in? Where are repairs required? What are the most critical works? Priority should be given to issues that may result in pollution or downtime."

Common complaints, such as corrosion in tanks, may lead retailers to initially look to replacement, but with the leading-edge protective coatings and linings, this is not always necessary.

Providing a fairly simple and cost-effective solution to a range of asset resilience issues; from preventing and dealing with existing corrosion, to stopping leaks; these linings will dramatically extend usable life.

The latest coatings can be used on practically any substrate, creating a usable surface within 24 hours it is touch dry within seconds.

This speed of application dramatically accelerates the process of repair, minimising downtime, and in some cases, mitigating it altogether. Linings will also stop fuel leakage and prevent water ingress ideal for tanks, flood defences and bunds.

For fuel storage tanks, there are specialist transformative solutions that bring tanks up to the highest levels of environmental safety.

Some, such as DOPA, TankTechnic’s double-wall lining solution, also include 24/7 remote leak-detection monitoring, to combat contamination, tampering and pollution.

"In general," says Scraftton, "monitoring equipment such as separators and tanks will provide accurate information as to asset status, flagging up small issues before they become big ones. Remote monitoring of tanks and pipes can also identify fuel leaks or theft. Sensors can be used to not only monitor equipment, but the surrounding environment temperature, soil quality, water table height, asset uptime and oil pressure, for example. This data will then help to inform optimised protection, performance and maintenance. Protective measures such as bunds should also be monitored.

"Fuel in itself is an asset, one that may get more expensive due to the current global and economic climate. Regular fuel testing and subsequent polishing will keep this precious resource in top condition."

Essential maintenance and protection

An important part of asset resilience should be planned maintenance. By taking a proactive approach to essential servicing, rather than waiting for things to go wrong, businesses will save money long-term, costs will be more predictable and downtime can be avoided.

Separators, for example, are key pieces of equipment for forecourts, according to Scrafton. "Regular cleaning and maintenance must be carried out as the consequences of blocked or inadequately working separators can be catastrophic, causing flooding and allowing pollutants to enter the environment.

"Flooding in particular has become more of a concern to many sites, as the frequency of heavy rainfall and super high tides increases as a result of climate change winter 2015/2016 saw some of the worst flooding the UK has ever experienced. Beyond separators, sites liable to rising waters should look to other solutions to protect assets, such as flood defences. A Flood Risk Assessment is a good first step in understanding the potential risk; how high the water might rise, for example; so the best and most cost-effective measures can be implemented."

The right response

Sometimes, disaster is unavoidable and part of asset resilience should focus on response to an incident. This is particularly important in forecourts in order to prevent pollution.

As a starting point, the correct spill kits should be on site, staff should be briefed on procedure, focusing on safety and then protecting assets where possible. Swift and appropriate action can stop disaster on a large scale and will speed up the process for emergency experts.

"Good business planning must look to the future," stresses Scrafton. "Never rest on the laurels of current markets, with contingency in place should things go wrong.

"This is true whatever the economic climate. Asset protection is a key part of this, and can actually contribute to improved environmental credentials, as well as reduced overheads. We all want to minimise waste, so avoiding replacement where possible has got to be a good thing. And, for the forecourt sector in particular, asset resilience should be viewed as a key step in pollution prevention."

No comments yet