Its forecourt is made from concrete mixed with pieces of recycled glass; its roof has 90 solar panels; and it uses low-energy lighting. However this is not some space-age prototype but a fully operational BP forecourt trading in Los Angeles.

It’s called Helios House and BP insists that it’s not a station of the future but rather a station of today, "that’s a little better". The BP blurb continues: "We started with the typical, everyday station and renovated it in an eco-friendly way - a little greener in its design and materials and in its use of water and energy. It’s a living lab where we can try out ideas for other stations and where people can find ideas they might want to bring into their own lives".

Apparently the idea for Helios House came from BP’s commitment to balancing society’s need for energy with a responsible approach to the environment.

The forecourt might not be ’of the future’ but it certainly looks very futuristic with its use of recycled stainless steel panels.

Other materials used include farmed wood from renewable sources, bathroom tiles made from 100% recycled glass and signage constructed from stainless steel scraps left over from the project.

The green roof is covered with drought-tolerant plants to help reduce the need for heating and cooling systems, to minimise rain water run-off, and re-oxygenate the air through CO2 absorption.

Helios House also exceeds US environmental standards for on-site collection, filtration and distribution of water. The canopy collects rainwater for irrigation plus the rain and site water is filtered to prevent hydrocarbons from polluting the groundwater.

As for lighting, the 90 solar panels produce enough energy to power two to three homes while the energy-efficient lighting in the canopy area uses 16% less electricity than traditional petrol stations.

Lighting throughout the station uses multiple circuits and sensors to automatically switch on or off as needed through a 24-hour cycle. However the design of Helios House makes use of natural light as much as possible, saving about 1,400 kilowatt hours each year.

In addition to all these design features, the forecourt is manned by specially-trained staff who provide customers with information and tips about greener living. So they do things like check tyre pressures and tell drivers that properly-inflated tyres help fuel economy.

Ann Hand, senior vice president for global marketing and innovation at BP says: "The whole site is really a lab. Everything we have on it is about re-use." BP would not disclose how much the development cost but said it was in line with "conventional construction". Unfortunately the company has no plans to use any of the design features in the UK at the moment.

However there are some interesting developments in forecourt design in the UK too. Harry Tuffins Supermarkets opened a striking new-build forecourt in Ludlow, Shropshire earlier this year. It features sweeping curves, stainless steel struts and plenty of glass. The company’s managing director, Paul Delves, comments: "We wanted something that looked really different and I think that’s what we have got. The site is the first thing you see when you come into Ludlow so we wanted it to make a statement."

The building features plenty of glass to allow natural light in but Paul says it’s triple-glazed so there are no heat problems as a result. The steel struts are more of a design feature than a necessity and the roof and brickwork are a nod to the environment.

"The brickwork on the back and along the sides of the building features a rolling hill design to give our neighbours something nicer to look at it. And the roof is coloured green rather than the usual grey," says Paul.

He says the company held discussions with the council before they submitted plans for the £1.5m project, to make sure it would be acceptable.

Obviously different designs suit different areas and Paul refers to Tuffins’ next major project - in the small market town of Cleobury Mortimer - as a case in point. "We’ll be building there next year but it will be a more traditional design than Ludlow so that it blends in more with its surroundings. However it will be different in its layout as we are limited on space. We’re planning on having retail space in the basement with a travelator and a car park on top."

A new development or even a redevelopment is a major project which is why many companies choose to bring in specialist project managers.

Leading project management company, Barlows, is celebrating its fourth year working in partnership with oil giant Total UK.

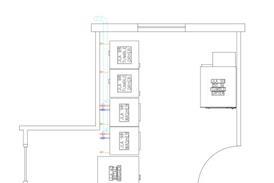

The relationship began when Total UK wanted to launch Bonjour c-stores onto its forecourts. Barlows turnkey service meant that its team could translate the original European design to the British forecourt market, while also utilising its ’lean’ approach to re-fit programmes which would ensure the forecourts suffered minimal trading disruption.

One of the major successes of the partnership was better co-ordination, which meant Barlows reduced its time on site from 18 days to just 4.5 days.

Sallyann Allman, head of business development at Barlows, explains: "Initially sites could be closed for anything up to 21 days, however through scrutinising the on-site programme and maximising the time before we reached site, we were able to complete a project in less than five days. It’s our opinion that this could only have been achieved through our partnered turnkey approach."

----

=== Case study - Gulf, Clacton ===

When it comes to development, there’s the physical building of the forecourt as well as the less-tangible development of the business. Patrick Pandya, owner of Pump Hill Service Station in Clacton, says he turned his business around with the help of Gulf and a company called Instore Profits.

Patrick was not a particularly experienced retailer and the opening of a Tesco superstore four miles away from his site, hit him hard. However despite this, Gulf identified his shop as a good potential revenue stream.

Patrick takes up the story: "Despite our strong relationship with Gulf we were reluctant to get it involved in any changes because we thought it would involve major investment. But after a lot of convincing we took the plunge and are ecstatic with the results."

Gulf introduced Patrick to Instore Profits, a specialist shops consultancy. The company’s managing director, Tony Bailey, comments: "Patrick’s business was typical of many smaller sites that are not maximising shop potential and are reluctant to make changes, either because they feel that it will require a significant investment or they cannot see the benefits of change. Pump Hill Service Station is in an area of high footfall and clearly had the potential to improve from its 2006 position - a weekly shop turnover of just £1,800."

With InStore’s help it’s now exceeding £5,000 a week.

The only investment Instore demanded of Patrick was his time and a more disciplined approach to shop management. Instore created a new layout and a fresh shop image, introduced planograms, stock control procedures and new lines.

"We were given expert help in obtaining an off licence and I now have a wide range of wines, beers and spirits; and sales are up considerably," says Patrick. "We also introduced pet food and it has become one of our strongest lines with a 60% margin."

Patrick has nothing but praise for Instore Profits’ work: "Our shop looks more inviting, stock moves more quickly, which has improved cash flow, and our turnover is up."

He says he follows the company’s instruction booklet like a bible: "Our improved understanding of sales and trends has made us more confident in trying new products and lines. For minimal outlay we are now profitable and the future looks healthy."

No comments yet