The forecourt environment is challenging to work in; changing conditions, dangerous substances and the general public can all pose issues to the contractors tasked with keeping these sites operational and looking good. Paul Harrison, from leading forecourt branding and signage experts, DRB UK, provides his top tips for ensuring efficient and safe operations.

A quick search on google demonstrates the potential dangers of carrying out works on a forecourt. Just recently, an engineering company was fined after a worker fractured his pelvis and suffered internal injuries after falling through a petrol station forecourt canopy.

An investigation by the Health & Safety Executive (HSE) found that there was no identification of a need for control measures to prevent employees falling from height - no risk assessment or method statement had been produced.

During the course of their daily duties, DRB engineers often find themselves on forecourt roof canopies, so this type of accident is a cautionary tale concerning the importance of preparation and procedure. Health & safety is the top priority, one which is thankfully shared by all of our most high-profile clients.

What are the main challenges?

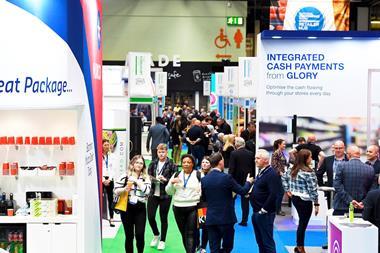

For DRB, a particular challenge is a necessity to work across the whole site – from the forecourt itself to any retail establishments and off-road signage. Branding, way-marking and lighting are everywhere and the team is often called upon to update everything. Zoning is crucial for this type of work, cordoning off a particular area and then moving on when the task is complete in order to keep workers and the public safe.

Most of the work DRB carries out takes place during opening hours, when the forecourt is busy with both customers and delivery drivers. Minimising operational disruption is therefore a priority, for example, DRB would only work on one fuel dispenser at a time, to ensure maximum uptime for the site.

The changing seasons are another variable, both in terms of hours of daylight and weather conditions. All of these different factors must be considered in the risk assessment.

Getting the risk assessment right

Before starting any works, a survey and pre-start meeting with the client should take place to get a better understanding of their expectations, the way the forecourt is run and the likely hazards which may be encountered. It is also important to meet with any other contractors on site in order to share working practices and create a mutually relevant risk assessment.

Overall, communication and engagement with everyone at the forecourt – from fuel delivery drivers to shop staff – is essential to ensure all eventualities are taken into account.

Confidence of conviction

As far as DRB employees are concerned, it is extremely important that they have the confidence and autonomy to take a stand if they see something unsafe going on. This is not the time for turning a blind eye or feeling uncomfortable confronting someone who is putting themselves or others at risk. Leadership and care are key characteristics needed in the people responsible for health and safety.

This honest approach should also extend to incident reporting, a point echoed by Rob Ramus, senior manager at BP UK. Following a review of major branding, upgrade works at BP’s busiest forecourt in Milton Keynes, Rob said:

“Safety is bp’s number one priority and always starts at the top. In the case of DRB, the team demonstrates a very strong safety culture that is clearly led by example. I was extremely impressed with the supervisor’s wealth of knowledge, but more importantly his positive attitude toward safety, ensuring his team understood the risks and managed them accordingly. Thank you to DRB for the fantastic safety leadership behaviours that I witnessed at bp Wavendon Gate in August 2022, long may it continue, as it does make a difference.”

DRB is part of the TSG UK Group, providing full forecourt branding, signage, hazardous area testing, EV charge installation, commissioning and maintenance throughout the UK.

For more information, visit: https://drb-uk.co.uk/

No comments yet