The fifth edition of the Blue Book, the industry bible on petrol station design, construction, modification and maintenance, was launched this month, and forecourt operators thinking of installing electric vehicle chargepoints should give special attention to Chapter 3, urges Jamie Thompson, chair of The Association for Petroleum and Explosive Administration’s technical committee.

In 1997 the Health and Safety Executive approached The Association for Petroleum and Explosive Administration (APEA) to produce industry guidance on petrol station design, construction, modification, maintenance and decommissioning. APEA worked with the Institute of Petroleum,now the Energy Institute, and produced the Bue Book in 1999. The publication has just been published in its fifth edition.

The changes the Blue Book has outlined over the years have enhanced public safety and environmental awareness, and the filling stations constructed over that period are recognised as being much improved.

There are however still causes for concern as fuel and design changes have caused challenges for petrol station operators.

The installation of EV chargers on petrol stations is a case in point. This development was foreseen of course and guidance has been issued in the latest and previous editions of the Blue Book, as well as industry codes – Electric Vehicle Charging Installations at Filling Stations, and Code of Practice for Electric Vehicle Charging Equipment Installation.

We have found that the first electric vehicle chargers installed were mainly on the larger sites such as motorway service areas run by the major operators, and there was an understanding of the risks involved.

Since then things have become more challenging as EV chargers are being installed on smaller sites where it is often difficult to find a position on the forecourt.

What appears to be a trend now is that chargepoint operators are approaching forecourt owners and leasing land on the filling station to install EV chargers which they will also cover the cost of. These businesses appear to be responsible for the installation, but, in some cases, it has been found that they are placing them in unsatisfactory positions causing public safety concerns.

At present the existing law does not recognise the installation of EV chargepoints as a ’material change’ to a petrol station that requires notification to the Petroleum Enforcing Authority (PEA). APEA believes that this could lead to unsafe EV chargepoint installations going unnoticed. We have written to the Health and Safety Executive expressing our concern about this potentially dangerous loophole.

My advice to operators is to check with your PEA if you are hoping to install electric charging equipment, because if installations are found to be dangerous later down the line a prohibition notice preventing use of the equipment could be issued.

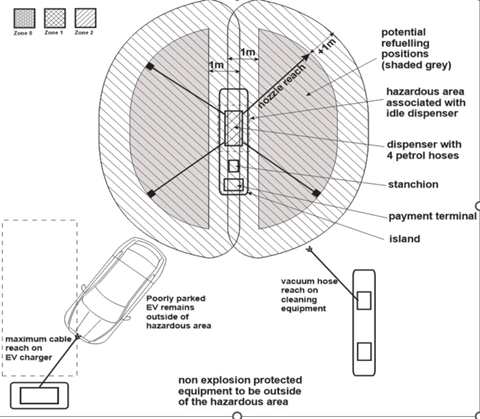

The rule is that EV chargers must be kept out of hazardous areas on filling stations, as they could be a risk to public safety by causing an explosion. Within the Blue Book there is clear guidance in Chapter 3 demonstrating hazardous areas on the filling station, and indicating the necessary distances the chargepoints should be given from tanks, pumps, road tankers delivering fuel to the site, vent pipes, etc.

The charger, the vehicle being charged and the full extent of the charging cable must be outside hazardous areas. And it should be remembered that hazardous zones can be temporary, as well as permanent.

Despite the guidance, we are coming across instances where EV chargers are placed inside hazardous areas and are a risk to public safety. One installer wrongly ascertained that lids covering tanks would mean that the tanks would not pose a risk to a nearby EV chargepoint installation. This is not the case.

Another common problem is not linking the emergency stop for the petrol pump and the EV chargers together.

Petrol station operators have a responsibility for the safety of the public visiting their sites and also neighbouring property.

They should read The Red Guide ’Guidance on managing the risks of fire and explosion’ – which is free to download from https://publishing.energyinst.org – to see what they should be doing with regards to ensuring their site is safe and that their staff have adequate safety training.

Since the 1990s petrol station design and construction has progressed, with improvements such as secondary containment for underground fuel tanks, and leak detection alarms. This makes the station much safer from leaks to the environment, reducing fire and explosion risks.

We are however finding that in some cases there is a lack of knowledge on site regarding what to do when alarms sound and also insufficient maintenance of detection equipment

One example we have come across was of staff removing a tank’s leak detector alarm to silence the noise. This was found on a routine safety inspection by the Petroleum Inspector.

Another more serious incident occurred at a motorway service station, with 14 double wall tanks with the necessary leak detection systems.

One of the managers heard the alarms and took no action other than to turn off the noise. When the Petroleum Inspector called and turned the alarms back on 11 of the 14 tanks were found to be leaking. There was a lack of training in this case.

Site operators have much to consider when running forecourts from marketing goods to making sure crime is kept in check, and they are often not experts in safety issues such as leak detection systems.

But my plea to the industry is to remind petrol station operators that safety equipment should not be just left to work, it must be maintained.

In this day and age, it is also possible to ensure when these alarms sound that an alert goes direct to a responsible person’s mobile phone or computer to make sure that appropriate action is taken.

- Jamie Thompson FEI, F.APEA, MIFire. E, was Principal Petroleum Inspector in London for 38 years. He has chaired the European Standards Committee on Petrol Tanks and Equipment for Filling Stations.

The Association for Petroleum and Explosive Administration was founded in 1958 by Petroleum Licensing Authorities and now draws membership from all quarters of the petroleum industry including regulators from national and local government, oil companies, equipment manufacturers, contractors, and petrol station operators.

Its objectives are to advance scientific and technical knowledge, to supply and interchange information and to encourage uniformity of standards interpretation and application.