Automated car washing and valeting on the petrol forecourt is making a huge comeback thanks to the closure of many hand washing operations and the fact that drivers are keeping their cars for longer and therefore need to take better care of them. According to the Car Wash Association, the number of hand car washing outfits has dropped from possibly 20,000 before the pandemic to around 5,000-6,000 now and, according to Autocar, the average car in the UK is 10 years old.

One company that is investing heavily in car washing and valeting is Lawrences Garages. Director Ben Lawrence says: “The government, with the help of local authorities, seems to be getting a grip on illegal hand car washes. Articles from The Guardian, the Salvation Army and the Safe Car Wash App have made the public understand what’s happening in many hand car washes in the UK. With this in mind, the public are now wanting a company they can trust and a place that has everything they need to valet their vehicle.”

All three Lawrences sites (Harleston, Sheringham and BP Sholing) have car washes but BP Sholing has a jet wash too and has lodged a planning application for two more while Sheringham has a planning application in with the council for a jet wash.

Ben says they have had car washes for more than 20 years but have renewed and refreshed their offering over that time.

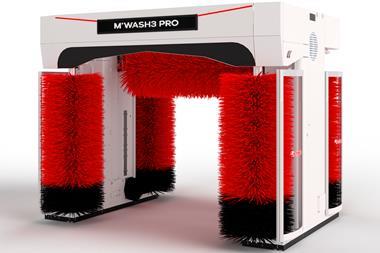

He has the Washtec Softcare Pro Classic 2.4m car wash with SofTecs Pur brushes. It also features the HP wheel wash 70 bar, XL wheel brushes 21”, special rim cleaner, Foamtastic foam curtain, LED Illumination Light Show (which Ben says offers great theatre for the family), full rotation dryer 360 degree and contactless payment terminal. The company recently upgraded to the My Washtec Remote Diagnostic and Access system.

“Our partnership has been mainly with Washtec; we’ve always had a close relationship with them and we communicate weekly about any concerns or strategy going forward.

“The Softcare Pro model is a German designed and manufactured machine with excellent quality in terms of performance and build. This is what we required because of the number of washes we do weekly/annually.”

Lawrences uses reclaim units on the car washes for efficiency and to save on water. And the Auwa chemicals used are environmentally friendly.

Ben says the equipment is very easy for the customer to use – and it’s contactless for extra convenience. “With the car wash, they just select a program and tap for payment, drive in and wash. Our jet wash is buy time so they choose how long they need.”

He adds that contactless payment is a big advantage and advises forecourt operators to get contactless on everything, including air, water and vacs. “All our sites are very busy and we understand that customers don’t want to wait behind customers with big baskets of shopping to pay for their wash. Contactless means they don’t have to do that.”

Ben says users vary: “With the car wash, we see many family vehicles such as 4x4s and SUVs. We also get a lot of vans in with drivers wanting to sit in the vehicle while the wash is happening; this is especially true for the top wash which includes polish and HP wheel wash with special rim cleaner.

“With the jet washes, we certainly see people who love their cars and really want to get involved with washing their vehicle. But we also get van drivers and taxi drivers who want a quick wash on a daily basis.”

The car washes offers three programmes costing £4, £7 and £10. Ben says 50% of sales come from the top wash; 35% from the £7 wash and 15% for the £4 wash.

Ben says that in the more affluent areas customers are happy to spend £10 on a top wash, but in the more challenging trading areas, where customers really care about their vehicles, they prefer to use the jet wash so they can give their car a total valet.

Lawrences runs their own promotions. They give customers a booklet which outlines the dos and don’ts of car washing. This also includes a stamp card – get three stamps and the fourth car wash is free.

Ben warns that the resurgence of valeting has put a strain on servicing so you need to keep a close eye on your machines: “Having an understanding about maintaining your units is key in this current climate.”

One big tip from Ben is to make your car wash and jet wash graphics different to your fuel supplier’s graphics. “You want to make it appear like it’s a valeting centre. This will make it a destination for customers and it won’t just look like a side-line for the oil companies. This is a great time to make a serious return on investment.”

Another tip is to look at the area your machine sits in: “No customers will put their vehicle into something that looks tired and unloved even if you have a brand new £60k machine inside.”

ADVERTISEMENT

AIR-serv introduces multi-bay jet wash enclosures

AIR-serv, the UK’s leading air, vac, and jet wash managed service provider, is pleased to announce the introduction of multi-bay jet wash enclosures to the UK product portfolio.

The multi-bay jet wash enclosure is styled to enhance the site aesthetics and encourage washing in all weather conditions. The UK designed and manufactured enclosures, when combined with AIR-serv’s latest Foam Lance Jet Wash, provide the ultimate end-user jet washing experience, whilst delivering a quick return on investment.

Exterior panels and glass screens can be branded to include any bespoke marketing design to further enhance the site’s appearance and include a clear marketing message.

The bays are 4.8m wide by 6.4m depth with a maximum wash height 2.7m incorporating LED interior lighting. This allows the washing of a wide variety of vehicles throughout the day and night.

Please contact your AIR-serv contact for more details 01942 722333 or email sales@air-serv.co.uk

Jet success

If you want to find out how much forecourts can make from jet washing then Electrajet is a good place to start. Michael Franks, director at the company, says his top forecourt locations can take as much as £60,000 a year from one single jet wash machine!

Franks says they have the only machine on the market that offers a genuine spot-free reverse osmosis final rinse, a feature which is especially useful in hard water areas where the scale in the water will leave water spots on the car when dry.

“We also offer the only dedicated wheel cleaner lance. The EJ Easywheels cleaning solution is a customer-safe wheel cleaner that, when it comes into contact with brake dust, reacts and turns red. This is now known as ‘bleeding wheel cleaner’ and adds to the overall theatre of the wash.”

He says that while the state-of-the-art Electrajet jet wash may look a little daunting to someone used to the traditional brush and lance jet wash, it’s actually very intuitive: “All the modes are clearly described next to the buttons and are colour coded to match the hose required.”

Franks says pricing is very much location driven but advises forecourt owners to not be afraid to charge a high but fair price. “There will always be someone doing it cheaper but if you have invested in the latest equipment and are using quality chemicals the customer will feel the benefit of this and return.”

It’s a buy-time model so the customer pays for the time and can choose any option they like. “This is great as the old programme-style washes were too limiting, with buy time the customer can choose to come in for a quick touchless snow foam and blast off or go through every mode.”

Michael says that a few years ago £1 in a jet wash machine would buy the consumer three minutes. Today, due to rising costs, that £1 will get you one minute 30 seconds and, in some instances, just one minute. He says typical spend is £6-7.

To maintain service at all times, Franks says regular maintenance and daily checks are imperative. “You can’t rely on the customer letting you know you have a leaking trigger, for example. We recommend a daily check either at the start or the end of the day – running through all the cycles to make sure it’s ready for your customers.”

A new partnership with Eurotank means Eurotank can now supply, install and maintain the Electrajet range of valeting equipment.

AIR-serv supports driver safety

National Highways, the government-owned company charged with operating motorways and major A-roads in England, is using digital gantry screens to remind motorists to carry out safety checks including checking tyres, while Transport for Greater Manchester is using illuminated traffic information screens located on busy roads and intersections to remind drivers to check their tyre pressure and screen wash levels to stay safe and legal.

Richard Sweet, general sales manager at leading air vending supplier AIR-serv, says forecourts can benefit from these information campaigns by offering modern air facilities and upgrade their machines to offer screen wash.

He says: “We all know that an air machine can help distressed motorists out of a short-term bind, to get them back on the road, however, the British Tyre Manufacturers Association reports that surveys have repeatedly shown 25% of vehicles have at least one tyre that is 25% under-inflated. This leads to increased fuel consumption, poorer vehicle handling and reduced tyre life. This equates to over 600,000 tyres and 1.5 million tonnes of CO2 being wasted in the UK every year due to tyre under-inflation, highlighting the need to proactively check tyre pressures.

“Forecourt staff can advise any motorists struggling to find the correct tyre pressure that this information is usually available in the vehicle manufacturers’ handbook or inside the fuel filler cap, or driver’s door sill.”

When it comes to screen wash, Sweet says many drivers prefer to purchase screen wash from an AIR-serv air machine so they are not left with an empty 5ltr plastic container to dispose of. There is also the fear of spillages from part-used open containers in the boot and the cost of the larger 5ltr containers when drivers can take a smaller volume from the AIR-serv Air machine at a lower price.

“AIR-serv preaches the importance of modern, digital and, most importantly, reliable air machines on forecourts to both support the motoring public and help forecourt operators to generate ancillary revenue.

“Advances in machine technology allow AIR-serv to monitor new revenue share machines to check usage and diagnose some issues before motorists and site operators report the machine as unserviceable.

“With forecourts increasingly focusing on the convenience side of their business, and the staff’s time more constrained, it makes perfect sense to partner with the air vending market leader leaving time for site operators to focus on the rest of their business.”

ADVERTISEMENT

Automated Car Wash Club Membership

PSD Codax has further revolutionised car washing with the introduction of contactless, License Plate Recognition (LPR) technology.

Now available in the UK, LPR from PSD Codax makes it easier than ever for customers to sign up for club membership and enjoy the ongoing benefits of a subscription. No attendant is required, making set up truly simple.

The PSD Codax camera and system is significantly more effective than other offerings, with a read accuracy of 97+% and seamless integration with our eCOM and back-office offerings.

Introduce LPR from PSD Codax and fully realise the remarkable benefits of simplified, recurring revenue!

Hand car washing

While the number of hand car washing operations has decreased, there are still many issues regarding the illegal part of that industry and particularly modern slavery. The Car Wash Association (CWS) says research published earlier this year called for the government to revisit a manifesto pledge to establish a single enforcement body (SEB) and transform the fragmented labour enforcement system in the UK.

A 2019 government policy paper committed to creating a SEB that would merge three major enforcement bodies: the Gangmasters and Labour Abuse Authority, the Employment Agency Standards Authority and the National Minimum Wage Unit at HM Revenue and Customs.

This new body would then address the whole spectrum of illegal behaviour by employers – from non-compliance such as non-payment of wages, through to forced labour and modern slavery, which is especially important in the context of non-compliant hand car washes (HCWs).

The CWA reports that progress on the SEB has stalled, despite commitments by successive governments and the shelving last year of a long-awaited Employment Bill that contained the elements necessary for the formation of the SEB. Despite this, debates on the legislative response to modern slavery and exploitation continue.

“There is a clear case for reform of the UK’s labour market enforcement landscape. Enforcement bodies, businesses and organisations representing workers are calling for a coherent approach that can address the whole spectrum of labour offences and provide clarity on employment legislation and modern slavery and auditing standards,” says Professor Alexander Trautrims, associate director (Business and Economies) of the Nottingham Trent University Rights Lab, and the CWA continues to lobby the government to revisit their decision.

Meanwhile, the office of the director of Labour Market Enforcement is seeking input into shaping the director’s strategy for 2024/25. This will be submitted to ministers by the end of November.

The director is hosting a series of stakeholder engagement roundtables in London this month to which the CWA has been invited. These roundtables will provide stakeholders with the opportunity to look at the key issues and present evidence to the director, in a forum that encourages open discussion and debate.

There are four themed sessions for which the CWA will be providing evidence of non-compliance with labour market regulations as well as emerging trends and risks.

Earlier this week, Theme 1 Recruitment was discussed in relation to online, offshore and overseas recruitment; right-to-work checks; digital exclusion; recruitment through social media; and recruitment fraud.

On June 15, Theme 2 Employment will be discussed. This will look at new models of employment, some involving intermediaries, ambiguous employment status, bogus self-employment, non-payment of minimum wage (eg due to deductions, unpaid hours), issues associated with remote working and lack of informative payslips.

On June 19, Theme 3 Communication will discuss the most effective ways to increase business awareness of their obligations to workers – carrot or stick? Also, how to reach workers most at risk of exploitation through formal or informal education and awareness-raising channels.

Finally, on June 22, Theme 4 Hidden High Risk Sectors will be looked at with a focus on what factors create the risks and how can they be addressed.

The CWA has also brought to the attention of the enforcement agencies the increased profitability of HCWs now that their numbers have dwindled from possibly 20,000 before the pandemic to around 5,000-6,000. This has allowed them to raise prices dramatically.

Alexander Russell, director of strategy at the CWA, says: “This new-found and additional profitability has in turn led to fears that they have once more become a magnet for traffickers to set up in order to be able to offer the lure of ‘employment’ to their migrant victims. With the delays in the formation of the SEB, this has once again raised the prospect of a revival in the numbers of HCWs that are likely to begin operations.”