Why investing in the latest technology is the key to car wash success

Back in the summer, Top 50 Indie Ascona Group, announced two new vehicle washing partnerships as part of improvements to its services across its forecourt estate.

Its new partnership with American-based PDQ Manufacturing led to it being the first forecourt in the UK to install the Laserwash 360 Plus. The new kit was installed at Hinton Service Station in Christchurch in Dorset, and the plan is to roll out the system to other sites under the Ascona Group’s brand, ‘Charlie’s Express Car Wash’ later this year.

At the same time, Ascona announced a strategic partnership with WashTec UK that saw it introduce a ‘first of its kind’ truck washing facility at its Tenby R-ad site on the A40 Eastbound in Carmarthenshire, which is said to offer the very best technology available to HGV drivers (see box page 62).

Colin Russell, director of sales and valeting at Ascona, says the investment in the new Electrajet jet wash equipment has been a great success as it offers customers the ‘most modern and flexible jet wash available in the market today’.

“We have raised the standard over the normal jet wash offer and now have specific programme options that the customer can choose dependent upon their needs. This includes separate snow foam, a specially formulated wheel cleaner application along with a final rinse with a RO Spot Free function for a perfect spotless finish.

“All of our valeting equipment uses contactless payment for ease and simple reconciliation of income”.

Colin says they have jet washes at 23 of their sites… and counting. “Our customers just love them. At each site, we also install a very highly specified rollover car wash

to complement our valeting offer. Like the jet wash, this offers contactless payments as an option.”

Best in class

He explains that Ascona is always looking for ‘Best in Class’ and as such is prepared to invest in the latest technology. “For example, our Hinton garage has seen the installation of the PDQ Laserwash 360 Touchless car wash. This wash and dry unit from PDQ Limited (a Dover Company) gives a fully automated touchless car wash experience for customers who prefer not to use the brush wash or the jet wash. The Laserwash 360 is well proven and offers a clean and dry car with additional theatre built into the wash programmes – it’s quick and quiet. Thanks to these innovations, our customers really like our valeting offer as we provide them with a first-class choice of programme to ensure they can really enjoy a clean shiny vehicle experience.”

He adds that regular maintenance and on-site staff training are vital to make sure that sites achieve maximum uptime and availability of the equipment.

Ascona’s wash facilities are promoted by the company’s social media channels and also by special one-off activations that are either offered across the network or are site- specific.

“All promotions are monitored so we can understand more of our customers’ needs and likes. Our jet washes also have a large top-mounted LED display screen that continually changes so we can attract our customers’ attention.”

Attention grabbing

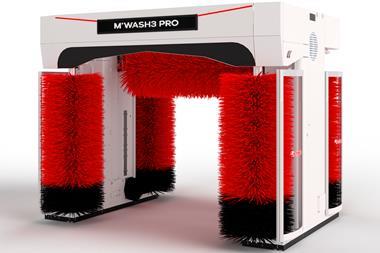

Another car wash that is bound to grab motorists’ attention is Istobal’s M’Wash 4 which boasts “smooth, clean lines and a cutting-edge design”.

Lindon Hett, director at Istobal UK, says the machine has garnered a lot of interest in the UK, specifically for its “highly technological advances, speed and convenient user experience”.

And the good news is that the company has just started to mass produce the M’Wash 4 rollover.

Says Hett: “The M´Wash 4 was designed to boost productivity and profitability in the car wash industry by offering maximum efficiency in every aspect. This advanced car wash enables higher quality car washing and drying in less time and in a sustainable manner by using a lower consumption of water, energy and chemicals.

“On a technical level, customers in the UK particularly appreciate the new high-pressure systems that provide more effective cleaning, with the side drying system that adapts to all types of vehicles. All this together with the better application of chemicals and its revolutionary 360° rotating horizontal drying. This latest rollover is the most technologically advanced in its range, achieving a higher quality in-car washing and drying in less time, with greater efficiency in consumption in a user-friendly experience.”

Forecourt operators, with an eye on rising energy costs will be mindful of how much a car wash costs to operate but Hett reassures them: “We champion the design and production of sustainable solutions. Our main goal is to reduce the consumption of water, energy and chemical products while promoting a more sustainable car wash sector. Ensuring we still offer a top-quality service with the lowest consumption of resources and simultaneously increasing the productivity and profitability of the business.

“In the past year, we have been strongly committed to innovating lower energy consumption in our washing equipment through the introduction of various technologies. As well as the reduction of energy consumption in the Istobal rollovers range, we have also achieved 32% in energy savings for the latest generation of jet-wash solutions with the incorporation of frequency variators that control the speed of the pressure pump motors dependent on the wash phase. Each wash track achieves more than 4,300 kWh of energy savings per year. Our Smartpulse system has helped save an additional 5% of energy by automatically managing the operation of the high-pressure pumps and chemical dosing pumps.

“Our R&D team focuses on environmentally friendly technologies, which effectively handle resource scarcity and allows water to be recycled, saved and decontaminated in wash facilities. Likewise, among other examples, we have 60ºC hot water aerothermal boilers that achieve up to 75% in energy savings compared to an electric boiler and 60% compared to a gas or diesel boiler. This sustainable and efficient system also reduces the maintenance of the equipment, lowering the environmental impact by using energy from renewable resources, rsulting in lower combustion and C02 emissions.”

Hett says they also work closely with customers to enable greater energy savings by using renewable resources. “Our most recent installation of an industrial truck wash in Spain is a prime example of this in action. This project involves our Istobal HW’Compak rollover that is operated only by the use of solar panels at full capacity and autonomously.”

He adds that Istobal is also a pioneer in the development of environmentally friendly technologies, providing the car wash industry with solutions to cope with water scarcity by recycling, saving and decontaminating water in car wash facilities. “This is significant because regions in Spain, France and the UK, as well as other countries, suffer from water restrictions due to extreme droughts and in some cases will also have regulations affecting the car wash sector.

“The need for sustainable car wash facilities in the UK is vital for businesses today. With the cost of bills skyrocketing, the need to lower energy consumption is at the forefront of everyone’s mind. With the advanced M’Wash4, we’re able to offer customers a solution to help with both the energy bill and saving water resources.”

FAST FACT: 360°Istobal’s M’Wash 4 offers 360° rotating horizontal drying

Ascona’s partnership with WashTec means truck wash success

Ascona’s new partnership with WashTec UK has seen it introduce a ‘first of its kind’ truck washing facility at its Tenby Road site on the A40 Eastbound in Carmarthenshire, which is said to offer the very best technology available to HGV drivers.

The truck wash uses a fully ‘closed loop’ total water recycling system, said to be the first of its kind in Wales, which recovers all water used within the wash process, filtering it for reuse with little or no water entering the mains drainage system. This system means customers get one of the more environmentally friendly wash operations.

Colin Russell, director of sales and valeting at Ascona, comments: “ The truck wash is now established after the initial opening. User numbers continue to grow with local and national accounts benefiting from this quality installation. Other locations are also in various stages of planning.”

Water treatment

Istobal says its range of water treatment equipment reduces the consumption of this resource and obtains water of the highest quality for ‘impeccable results’ in vehicle cleaning. Additionally, by including recycling systems in its installations the car washes can operate during periods of water restrictions.

Lindon Hett, director at Istobal UK, comments: “For Istobal, the consumption and quality of the vehicle wash also depend on the quality of the water used in the installation. For this reason, the group has developed various water treatment systems, such as its biological recycler with an ultra-filtration system capable of recycling up to 100% of the water from exterior vehicle washing. This innovative, state-of-the-art recycling system achieves maximum water quality for subsequent reuse in all washing phases, including osmosis in the final finish and saves up to two million litres of water per year in each rollover.”

He says cleaning a vehicle in a sustainable car wash that incorporates water treatment solutions generates less water consumption. “Compared to a manual car wash with a private hose this is 500 litres of fresh water per wash or up to 30 litres in a standard car wash with a water recycling system. It also reduces the contamination of the water from the wash process by passing it through a hydrocarbon separator system that reduces the presence of this compound by 94%. The technology for water treatment and recycling in the car wash sector exists at competitive prices, making it in many cases a profitable investment and giving viability to car wash businesses, where water scarcity is increasing and leading to higher operating costs for this resource.”

FAST FACT: 5% Istobal’s Smartpulse system has helped save 5% of energy use

No comments yet