Forecourt equipment supplier Gilbarco Veeder-Root (GVR) is warning petrol station operators that outdated detection equipment is failing to spot water contamination in fuel tanks.

It says that when visiting sites its engineers “frequently encounter” so-called phase separation in fuel blends containing ethanol, such as E10 which has 10% ethanol, 90% petrol.

Caused by water contamination, the problem can cause serious complications if left undetected it says, leading to fuel degradation, microbial growth, corrosion, and operational issues in engines using the fuel. This in turn, GVR says, leads to customer vehicle breakdown, discontent and brand reputation damage.

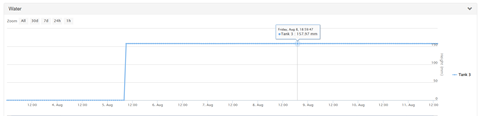

When phase separation occurs, the mixture can split into two distinct layers, one of petrol and one of ethanol-water, and traditional water detection floats, designed for pure water, often miss this subtle but damaging separation because the density is different from water alone, says the company.

It adds that its analysts have identified suspected water contamination at several major UK retailer sites over the past 12 months. GVR engineers were then dispatched to these locations to test the tanks and help prevent further issues caused by the contamination for the retailers.

To prevent the problem, GVR says it “strongly recommends” retailers upgrade to float detection systems such as its 2-Phase Separation Float, which uses weight technology to detect not only water but also phase separation.

When sites are found to have the problem it recommends that they close until investigated by an engineer. And it adds, that regular inspection and maintenance of underground tanks are essential to prevent water contamination.

GVR points to numerous reasons for phase separation:

- Cracks or faulty seals in the tank or its access points can allow rainwater to seep into the tank.

- Temperature changes can cause moisture in the air inside the tank to condense and accumulate as water at the bottom.

- If the tank is located in a flood-prone area, floodwaters can enter through openings or damaged sections.

- Faulty or old tank monitoring equipment.

- Poor tank maintenance. Corrosion or damage to the tank walls can create leaks allowing water to enter.

- High groundwater levels can lead to water entering through defects in the tank or its fittings.

- Damaged or improperly installed fill pipes and vent systems can allow water ingress.

- Water may be introduced during fuel delivery if the fuel supplier’s storage or transport systems are contaminated.