Your primary (tank), secondary (bund) and tertiary (separator) containment systems are your first, second and third line of defence against environmental pollution. So says Shirley Miles, head of environmental protection, at Adler and Allan.

She says regular asset maintenance is essential to keep all pollution prevention equipment working at optimum efficiency, safeguarding operations handling and storing oil or other hazardous materials.

What does the law say?

Two of the key pieces of legislation that could land you in hot water if you don’t properly maintain your primary, secondary and tertiary containment are:

• The Water Resources Act 1991 which states that ‘It is an offence to cause or knowingly permit any poisonous, noxious or polluting material, or any solid waste to enter any controlled water.’

• The Environmental Permitting Regulations 2016, which state that ‘It is an offence to cause or knowingly permit a water discharge activity or a groundwater activity without an environmental permit.’

“A pollution incident because of a poorly maintained asset or inadequate containment is a strict liability offence and failure to adhere to standards and good practice guidance is a key factor in considering enforcement action,” explains Miles.

“The onus is on operators to demonstrate compliance with regulation to reduce the risk of a pollution incident. A robust asset maintenance programme is essential for providing the information needed for service log scrutiny in the event of an incident or during routine environmental inspections.”

The implications of failing to adequately protect the environment include environmental, legal, financial and reputational damage.

Miles points to the fact that there has been a marked increase in the level of fines over the last decade, especially for large companies: “In certain circumstances, senior officers of offending businesses have been held personally liable.”

CIRIA C736 guidance (developed to assist owners and operators of commercial facilities storing substances that may be hazardous to the environment) is applicable to the containment of a wide range of inventories and to all sizes of sites from small commercial premises with a single storage tank, through to large chemical or petrochemical sites as well as warehouses storing hazardous substances.

Primary (tank) guidelines

Miles says primary containment is the most important means of preventing major pollution incidents and includes equipment in direct contact with the substances being stored such as tanks, vessels, pipework, valves and pumps as well as equipment that prevents the loss of contaminants under abnormal conditions.

Tanks are subject to various regulations, standards and good practice guidance – from COMAH, BS EN 14015:2004, EEMUA, API 650 and the Oil Storage Regulations, depending on the contents and tank material.

“You should carry out routine inspection and maintenance of containers and keep a record of when and who carried out the work,” says Miles.

“You should always look out for any signs of damage or interference to your tank or pipework, ensuring repairs are carried out immediately by a competent, qualified technician.

“As well as a weekly visual check, you should use a qualified technician to carry out a detailed annual inspection and service of your storage facilities, including:

• checking the condition of tank surfaces and supports for pipework

• checking the condition and operation of pipework and fittings

• removing and disposing of any condensation water or sludge in your tank

“You should receive a report about your tank which details any faults that must be fixed before you can continue to use your storage tank.”

She advises that qualified technicians should be a member of a professional scheme for qualified tank installers, such as the Petroleum Equipment Installers and Maintenance Federation (PEIMF), Engineering Equipment and Materials Users Association (EEMUA), or the Oil Firing Technical Association (OFTEC).

Using the latest high-pressure or ultrasonic technology, skilled engineers and specialist welders test for leaks and structural concerns, repair faulty tanks and provide full follow-up documentation.

Inspection and reporting services should be compliant with EEMUA Level 2, API and NDT standards and cover tanks used for fuel, water, chemical and food storage.

Adler and Allan’s proprietary, ultra-sensitive, ATEX Zone 1 AdlerView camera can be used to remotely inspect and clean fuel tanks – both above and below ground – from a van positioned up to 50 metres away. Clients receive a full report and video of their inspection and a faster, more exact diagnosis of issues.

“The cutting-edge approach also bypasses the cost of removing tank lids, as well as the health and safety risks of traditional man-entry inspections,” says Miles.

Non-Destructive Testing (NDT) analysis methods evaluate the quality of materials, fabrication, and integrity of tanks, pipelines, and wells, without destroying their serviceability.

Various techniques are employed including fibre optic, ultrasonic, and magnetic flux leakage to scale tank walls and deliver precise views of confined spaces and hard-to-reach or remotely accessed areas. Degradation, corrosion, weaknesses and welding defects are identified before damage occurs, avoiding unexpected repair costs.

Effective tank linings protect against deterioration and resist water and chemicals, keeping your assets performing for the long term. Glass-reinforced plastic is a resilient internal tank lining solution that offers a seamless, ceramic-like finish to confine even the most aggressive substances – ideal for bunded chemical tanks.

Specialist tank cleaners employ proven man-entry and non-man-entry techniques including gamma jetting, 360⁰ cleaning heads, and state-of-the-art robotic systems to tackle requirements such as changes of stored product, contamination, deterioration, decommissioning, transportation, or standard upkeep.

Secondary (bund) guidelines

A bund is a facility (including walls and a base) built around an area where potentially polluting materials are handled, processed or stored, for the purposes of containing any unintended escape of material from that area until such time as remedial action can be taken.

The Containment of Bulk Hazardous Liquids at COMAH Establishments containment policy supporting guidance for secondary containment states that:

All above-ground storage tanks (ASTs) should be bunded to provide secondary containment.

Bunds shall be subject to a routine and periodic inspection and certification regime by a competent person regarding their condition and performance.

During the inspection operators would be asked to provide demonstration of inspection criteria and inspection procedures. This should include both routine inspection and periodic detailed review that the structure remains fit for purpose.

Bund wall and floor construction and penetration joints should be leak-tight. Surfaces should be free from any cracks, discontinuities and joint failures that may allow relatively unhindered liquid trans-boundary migration.

As a priority, existing bunds should be checked, and any damage or disrepair, which may render the structure less than leak-tight, should be remedied.

Regular inspection and cleaning is key to an effective bund maintenance programme, ensuring that your secondary containment system is structurally sound and free of contaminants.

Working with a qualified person to train your engineers or carry out routine and periodic inspections of your bund’s condition and performance means defects can often be identified at an early stage and addressed before they become more significant and compromise the integrity. Inspections will be carried out in line with CIRIA C736 Containment systems.

Powerful vacuums extract water or leaked tank contents, before the entire structure is jet washed to achieve a complete clean, even in the most confined, inaccessible spaces. All breached volatile or toxic liquids – such as acids, inflammables, and dangerous chemicals – should be safely removed and treated, leaving the bund clear, functional, and risk-free.

Because many bunds were constructed more than 20 years ago from porous brick or concrete, a high number require regular reinforcement to perform at their best.

Adler and Allan’s polyurea AdlerCoat technology provides a cost-effective, durable and hard-wearing bund lining, with water, chemical, oil, and solvent resistance protecting the environment and your assets against deterioration, degradation, and structural weakness.

Tertiary Containment (separator) guidelines

Tertiary containment measures minimise the consequences of a major incident that causes the failure of or exceeds the storage capacity of secondary containment and enables additional measures to be deployed in time if an incident escalates.

Separators can form an integral part of a tertiary containment strategy. They are designed to trap harmful light liquids before they enter the surrounding area.

Regular separator maintenance is essential to keep all pollution prevention equipment working at optimum efficiency. Separator maintenance, including separator cleaning, also provides the information needed for service log scrutiny during environmental inspections.

The current standard by which separators should be operated and maintained, is BS EN 858-2:2003 Separator systems for light liquids (e.g. oil and petrol), it states separators should:

• Be fitted with an automatic warning device/high level alarm

• Be serviced and maintained as a minimum on a 6 monthly basis

• Be subject to a maximum interval of a 5 yearly integrity test

• Have full service and maintenance records available for inspection

Miles says there has recently been an increased number of pollution incidents where failed separators have been the cause or has exacerbated a loss of containment and regulators are clamping down on poorly maintained and non-compliant operations.

Proactive separator maintenance

A separator alarm system monitors oil, silt and liquid levels within underground separators, ensuring they are operating correctly and preventing pollutants.

Miles says you should work with an experienced partner who can specify, supply, install and service oil separator alarm systems and provide the necessary services to ensure your alarms are working properly.

“Look for an environmental partner that can provide a full ‘peace of mind’ service package, appropriate to the separator type and setting. The six-monthly inspection should be a non-intrusive, ‘in-service’ inspection to check levels and functionality of key components.

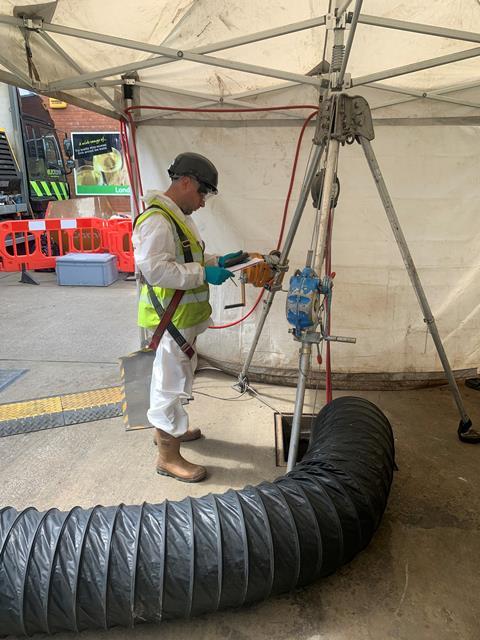

“The five-yearly integrity inspection is a critical service, as there are several faults that can develop within the body of the tank, such as fractures, displacements and ground water ingress that would compromise the tank but are not possible to detect during a six monthly inspection.

“The five-yearly inspection is an ‘out of service’ inspection. However, due to the adoption of latest technology and methodologies, the right partner will generally be able to complete the service within a day, causing minimum disruption.”

Operators are provided with full record of inspection and testing to satisfy regulatory and standard auditing requirements.

“Adhering to the guidelines on regular maintenance of your primary, secondary and tertiary containment systems should reduce the enforcement imposed in the event of a pollution incident.

“An environmental partner will provide its clients with services to reduce the risk of an environmental incident. However, if a strict liability event does occur, the inspection and service records demonstrating all reasonable endeavour has been taken to implement the proper systems for avoiding the incident will be invaluable in providing mitigation if enforcement action was considered.”

Integrity of tanks

Eurotank says it is seeing increasing numbers of its retail customers with single-skin tanks thinking about the integrity of those tanks, and the environmental impact they could have in the future.

Group sales director, Jack Aplin, says: “In a lot of cases retailers don’t know the age of their tanks and have never had any kind of condition report completed on them. This causes a dilemma for the site owner to decide what action needs to be taken and how much investment is required.

“A lot of owners believe the only options are to re-line the tanks or to simply do nothing. However, we believe the best option is to first find out the condition of your single skin tank, so an informed and calculated decision can be made.”

Aplin explains that Eurotank engineers often find that once tanks are emptied, and years of compacted sediment and rust are removed, micro leaks are identified. “We can reinforce these areas with GRP doing localised repairs and effectively stopping a minor issue before it becomes a major issue. Our engineers inspect the steel shell in fine detail, taking notice of the depth of pitting corrosions. Areas that are considered ‘deep’ can be reinforced with GRP repairs that will effectively stop the corrosion in the area completely.”

He says steel tanks generally fail due to spot corrosion. “Failed tanks can nearly always be repaired without the need to complete a full re-line. The main benefits of our tank re-tightening service are that failed tanks can be put back into use very quickly, the cost is low in comparison to full replacement or re-lining, and our experience is that re-tightened tanks have not failed again.”

Aplin says this re-tightening process has multiple benefits: the tank is fully cleaned; the thickness of the tank shell is measured and compared to its original thickness; internal corrosion can be inspected and pitting areas risk-assessed; localised fibreglass patches can be applied in the tank to upgrade risk points; and tank lids and fittings are cleaned as part of the lid removal and replacement.

Says Aplin: “The re-tightening process can be even more beneficial to operators that have multiple sites with single skin tanks as the re-tightening process costs significantly less than tank lining. Once the assessment work has been completed, companies can budget and make real plans for spending money on the right tanks at the right time.”

One company that is impressed with the tank re-tightening service is Top 50 Indie Highway Stops. Development director, Tony Head, says: “We have 11 sites with a few more in the pipeline, and we have a rolling programme of maintenance across those sites, managed by Eurotank. It’s really all about good housekeeping. Eurotank engineers come along and check inside all our tanks, clean them and do whatever’s needed to give them a clean bill of health. Some tanks will need relining but not all of them and we take Eurotank’s expert advice on that.”

Tony says tank inspections are especially important now with the biofuels that are in use. “Having Eurotank assess our tanks provides us with a lot of comfort. At the end of the exercise, they always give us a full report with pics so we can see exactly what’s been done.”

Tank re-tightening can be either a standalone service or done as part of both the Fastliner and Dopa Light systems that rely on the existing host tank as part of the double-wall system.

From Lifeliner to Fastliner

Indeed, Eurotank Environmental’s suite of tank lining products ensures the company can provide the correct solution for any tank owner’s needs. From Lifeliner, which is a retrofit, structural ‘tank-in-a-tank’ tank lining solution, to non-manned-entry installed Fastliner bladder tank liners, to single skin epoxy, Eurotank has a solution to fit any budget, appetite for downtime or future plans for the site.

The lower cost systems available from Eurotank are Sprayliner, Dopa Light and Dopa, which each come with a 10-year warranty. Sprayliner is a single-skin system that uses an epoxy coating sprayed onto the existing steel tank to protect it from further corrosion.

The Dopa Light vacuum monitored system uses an aluminium interstitial layer glued to the steel tank and a single skin of epoxy resin is sprayed onto the aluminium. Plastic interstitial tubing is used to communicate to a leak alarm installation in the kiosk. The Dopa system is the same but with the addition of an epoxy topcoat for extra peace of mind.

All three systems are quick to install thanks to the epoxy coating being applied using an air spray system to deliver a smooth pastel finish.

The company’s flagship Lifeliner system is a new resin composite tank built inside an existing tank, monitored by a class 1 pressure monitoring system as standard, and comes with a 30-year warranty. Lifeliner is also available in a single-skin version, which comes with a 20-year warranty. With the existing steel tank as a mould, three layers of hand-laid fibreglass and resin create a new single composite tank.

One of the main benefits of Eurotank’s tank lining offer is that even Lifeliner can be installed on live sites so that retailers can continue trading throughout. “We keep disruption to retailers and their customers to an absolute minimum by using a container craned into position over the top of the tank manways using our lorry-mounted crane,” says Aplin.

Other recent developments in tank services from Eurotank Environmental include robotic tank cleaning, remote tank cleaning service that is every bit as effective as manned entry, reducing tank downtime because cleaning is 45% faster than man entry methods.

The company can combine robotic tank cleaning with its Fastliner tank lining system, which can be installed without entering the tank, to provide a fully no-man-entry tank clean and lining installation on live forecourts.

No comments yet