We’re all susceptible to the vagaries of the British weather but our winter weather poses specific challenges for forecourt operators. Equipment needs to be able to withstand harsh conditions to ensure sites run smoothly.

Rain, ice and freezing temperatures can wreak havoc on dispensers, EV chargers and wash systems, turning minor issues into costly breakdowns. The solution according to Cheryl Ashton, marketing coordinator at TSG UK, is a proactive maintenance strategy that keeps your site running smoothly when the weather is at its worst.

“Low temperatures make components brittle; condensation can freeze inside equipment and blockages become more likely,” she explains. “Lighting failures compromise safety, while frozen pipes and clogged filters disrupt service. For busy forecourts and EV hubs, downtime does more than disrupt service; it erodes customer trust and cuts into revenue.”

Ashton says planned preventive maintenance (PPM) is the smartest defence against winter disruption.

“Instead of waiting for faults to occur, carry out PPM schedules inspections and servicing while equipment is operational. This approach identifies wear and tear early, extends the life of dispensers and chargers, and reduces emergency callouts. It also creates a predictable routine, enabling operators to manage budgets effectively and avoid costly surprises. Winter is unforgiving on forecourt equipment. A robust PPM strategy is not optional; it’s essential for keeping sites safe, compliant and operational in extreme conditions.”

TSG UK advises operators to ensure they make the following checks before any really bad weather:

• Dispensers – inspect hoses, filters and seals for signs of wear. Replace brittle components and check calibration to prevent meter drift.

• EV chargers – test transformers, circuit breakers and cooling systems. Confirm load balancing and inspect connectors for damage.

• Wash systems – check brushes, nozzles, drains and detergent levels. Run test washes to ensure full contact and correct soap application.

• Forecourt infrastructure – inspect lighting, signage and canopy structures. Clear drainage channels and verify that interceptors are functioning properly to prevent flooding.

• Simple daily checks, such as cleaning equipment, verifying payment terminals and clearing obstructions, can make a big difference. Combine these with scheduled professional servicing for maximum resilience.

Winter conditions heighten safety risks, says Ashton. “Damaged cables, corroded fittings or poor lighting can lead to accidents. Regular maintenance helps operators stay compliant with health, safety and environmental regulations, avoiding penalties and protecting reputation. For EV hubs, new Public Charge Point Regulations demand 99% uptime for rapid chargers, a target only achievable through robust maintenance.”

Contracts put you in good stead

Service providers will always say that having a maintenance contract will put you in good stead to ensure your forecourt stays open and operating at all times.

And forecourt operators agree. Kumar Sharma from Top 50 Indie Sharma Garages Group says his sites are all ready for the winter, helped greatly by the maintenance contracts he has in place.

“They take a very proactive approach, replacing things like ACO channels on the forecourts. The most common problems we get across our forecourt estate are damaged signage, needing to replace forecourt and shop lights, and electrical issues, but we have this all covered thanks to your maintenance contract.

Meanwhile, Top 50 Indie number one MFG is keen on PPM and so has just signed a new deal with Eurotank, which see interceptor and valeting PPM at an additional 185 Morrisons sites from January.

Helen Love, infrastructure manager – technical services at MFG, says: “Eurotank has consistently delivered exceptional standards of service and professionalism. We are pleased to expand our partnership, which continues to support the integrity and efficiency of our network operations.”

Eurotank’s interceptor and drainage division now has 1,324 sites on recurring revenue contracts, with MFG accounting for 836 of those.

Jack Aplin, Eurotank’s group sales director, says: “There is always a big focus on the cost of doing this type of work and we are very competitive, but the main benefit we offer our clients is we always remove all the waste so they don’t have reactive callouts between PPMs. This is where our customers get the most value out of our service.”

PROMOTIONAL CONTENT

![]()

Global-MSI is the contractor of choice for forecourt structure alterations, refurbishment, maintenance, damage repair services and structural design inspections.

Global-MSI maintains a unique and comprehensive reference library of original drawings and structural calculations for thousands of petrol filling stations across the UK, constructed by us and others. Accessibility to this unique resource enables a prompt response when structures require modification or repair, minimising disruption and eliminating expensive intrusive site surveys and multiple site visits.

Global-MSI has drawing and design information for most the UK’s forecourt canopies, as well as many shop and car wash buildings. So, whether our customer requires a structural design report or wishes to modify, repair or maintain their forecourt structure, the likelihood is that Global-MSI possesses the original design details. This enables replacement of damaged or weathered parts with identical materials that maintain the original design intent. Our experienced surveyors are conveniently located to offer a nationwide service, whether to assess accident damage or to discuss an alteration or refurbishment of an existing structure.

In conjunction with our Petrol Sign division, which specialises in the manufacture and installation of company branding, we offer a fast-response reactive service covering accident damage repairs and all forecourt branding requirements.

Shocking sights

As with all things in life, you get what you pay for and Edward Wheeler, Eurotank’s group managing director, says that since Eurotank launched its interceptor and drainage cleaning division, its engineers have been shocked at what they have sometimes found when attending sites that already have a PPM contract in place.

“When we made the decision to invest in an interceptor and drainage division I didn’t really know a lot about it other than who the main companies were who provided the service and that it was something I knew all of our customers had to spend money on.

“After three years, what I now know is that most, if not all, of our customers haven’t been getting what they thought they were for PPM visits.

“As with everything underground on the forecourt, out of sight is out of mind and there is very little oversight of what work happens because nobody can see it. Interceptor maintenance is even more difficult to see, particularly what the condition of the interceptor is on the bottom because it is full of water.”

Wheeler explains that if there is a large fuel spill, the fuel enters the drainage channels and is directed to an underground interceptor, which is full of water. The fuel pushes the water out leaving it contained within the interceptor rather than getting into the main drains with potentially catastrophic consequences.

“The drainage systems are a key control measure for protecting the local environment around the petrol station from explosive vapours and liquids getting into the domestic system. Maintenance of these systems is critical to ensure that, in the event of a large spill, the system will work as designed,” he explains.

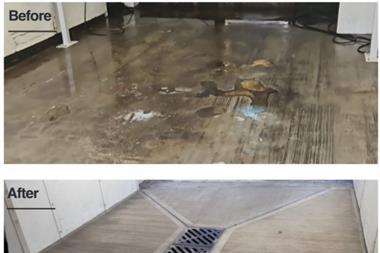

Aside from spills of fuel, heavy rain needs to be captured and diverted into the underground drainage system to prevent flooding. If the system gets silted up, during periods of heavy rainfall, the water has nowhere to go and flooding can occur.

In addition, the cost of disposing solid waste, like the type you find in interceptors and drainage channels is expensive. Some well-known waste disposal companies can charge in excess of £300 per tonne for disposal.

“What we’ve discovered is that PPM in the market is generally poor because proper cleaning out of the systems isn’t happening each time there is a PPM. The key driver of this is the price that fuel retailers appear to be used to paying for this service. Without spending too long on this point, the bottom line is that the cost to carry out a PPM fully is higher than the market rate for the task. This has resulted in apparent short cutting of the service.”

The right equipment

The first, most obvious way that a PPM is not done properly, is the cleaning out of the drainage channels. These get silted up with sediment very quickly and you need a jetting system on the tanker to be able to clean the channels, unless you spend hours removing the channel covers, which is very time consuming.

“When you are in the business, it’s easy to notice that a lot of tankers carrying out PPMs don’t even have a jetting system on the tanker, so even if the operator wanted to have their drainage channels jetted, they don’t have the equipment on board to be able to carry out this task,” warns Wheeler. “The second main area of short-cutting is not actually emptying the interceptor.”

To clean out the build-up of sediment in the interceptor, you first need to empty all of the water out of it. You can’t uplift it and take it away because the cost of disposal would be too high and you need to recharge the interceptor with water after the clean.

“Many tankers we see carrying out this service do not have big enough tanks to uplift and hold water and, at the same time, remove the waste. In reality, all they can do is ‘skim’ some water and hydrocarbons present off the top.”

If the sediment isn’t removed and stays in the bottom, eventually the sediment builds up so much that the capacity of the interceptor is significantly reduced and doesn’t conform to the design standard. In the event of a large spill, fuel potentially wouldn’t be trapped on site and could get out into the environment.

Based on feedback from multiple Eurotank customers, their experience was that they paid for PPMs but they would also be spending a lot of money on reactive callouts, with very large waste disposal costs.

“I’ve had a lot of discussions with retailers about the price of our interceptor service but generally the people focused on the price do not know what they are actually getting for their money, and the customers that use us know they are saving money overall and have hardly any reactive callouts as the systems are being maintained correctly,” says Wheeler.

Pump maintenance

Installing new pumps on your forecourt is a significant investment – and there are several factors to consider when selecting a pump with maintenance being one of the most critical, says Stu Viney, head of sales at Petroassist UK.

“Many retailers have previously opted for pumps at an appealing initial price, only to discover later that replacement parts are difficult – or even impossible – to obtain. This leaves few, if any, viable options for ongoing maintenance. It is worth remembering the principle of “safety in numbers”: maintenance providers are generally reluctant to support equipment with a very limited installation base.”

When asked why forecourt operators should have an equipment maintenance contract, he says: “Consider this – a single pump motor or tank gauge probe can cost more than an average annual service contract. Is it worth taking that risk on your site?”

Petroassist UK provides nationwide coverage via a team of experienced, field-based service engineers, all of whom are cross-trained to work on major makes and models. With over 40,000 callouts attended each year, its vans are fully stocked to maximise first-time fixes.

Viney says the most common callout issues are:

• filters, as modern fuels with higher bio-content require more frequent filter cleaning or replacement

• hanging hardware – nozzles and hoses experience heavy daily use and must be replaced periodically

• VR2 systems – these require routine calibration and testing to ensure optimal performance.

• Outdoor payment terminals – touchscreens and printers are prone to wear and require regular servicing.

Global-MSI’s canopy recovery

The canopy on a forecourt is more than just a shelter under which customers can fill up their vehicles. It – along with your pole sign – is usually the first thing that customers see, communicating your fuel brand and your high standards. However, canopies are prone to damage, particularly by high vehicles and that’s where Global-MSI can assist.

BP contacted Global-MSI to ask if they could help one of their dealers. The dealer’s canopy had been severely damaged after a strike by a high vehicle trying to enter the site. The site was closed for safety reasons, so the dealer had contacted BP for assistance who in turn asked Global-MSI to assist. This was made simple due to the original canopy details being available in Global-MSI’s unique library of petrol station structure drawings.

After an inspection, the engineer’s survey report and photos arrived back at Global-MSI where experts determined the level of work and materials required to complete the repairs. Part of the survey also included a full canopy condition report for the client.

This investigation identified the fact that the existing gutters were corroded through and several of the roof sheets had issues with corrosion. It was agreed that Global-MSI would replace the gutters, roof sheets and underlining sheets at the same time as its team repaired the canopy damage. The quote for the full repair including the additional works was quickly produced and issued to the dealer within one week of the accident taking place.

Once approved by the client’s insurance company, a combination of Global-MSI’s structural and signage teams were dispatched to the site. Once the signage was removed, the Global-MSI structural engineers started to strip down the damaged structure. Using a crane and specialist skills gained from decades of experience in this kind of repair, the engineers soon had the damaged parts removed and new canopy in place. Care was taken to make sure the customer’s trade was affected as little as possible while ensuring the safety of the public and operatives. Once the main structure was back to its original condition, the team quickly moved on to replacing the roof sheets and gutters. Finally finishing off the under sheeting to complete the project.

From the accident taking place to the canopy being fully repaired and refurbished, it took just 10 working days (five days to attend and make safe/quote, with five days on site to repair and refurbish the canopy).