The health and safety regulations that apply to forecourts range far and wide. And so they should, considering the mix of flammable substances, moving vehicles and members of the public that are present. And that’s before you add any car wash and valeting equipment, EV charging and the all-important convenience store.

Compliance is obviously paramount – if you want to stay in business. Non-compliance could result in fines, damage to reputation through negative publicity and, worse than that, accidents and even deaths.

According to the ACS’s Assured Advice on Managing Health and Safety, your obligations with regard to the health, safety and the welfare of your staff and customers are contained in the Health and Safety at Work Etc Act 1974. And the most important thing to know about that law is that everyone is responsible for ensuring the safety of others. So if anyone working in your business sees something that could cause harm to them, a colleague or a customer it is their responsibility to report it and make sure it is safe.

This should really be encouraged for the benefit of everyone – and the business.

Training is vital. According to the Health & Safety/Executive (HSE) colleagues need to have received training on the correct safety procedures for any of the following tasks for which they are responsible:

• Operating dispensing equipment, and recognising and reporting faults;

• Recording tank contents and meter readings;

• Using other site equipment, and recognising and reporting faults;

• Dealing with potential danger, including the use of firefighting equipment, dealing with leakages and spillages, notifying the emergency services and recording accident damage;

• Procedures when delivery of petrol takes place – only people appointed and trained as ‘competent persons’ under the appropriate regulations may receive deliveries;

• Procedures for dispenser switch-off, tanker parking, tanker and tank dip checks or gauge readings, petroleum certification and completion of fuel stock control records;

• Site opening and closing procedures;

• Dealing with customer queries regarding safety.

And a record of this training should be maintained by the employer.

Positioning EV chargers

Of course, dealing with the storage and handling of petrol and diesel should be second nature to any seasoned forecourt operator but what about EV chargepoints?

Jamie Thompson, APEA (Association of Petroleum and Explosives Administration) technical committee chairman, says APEA’s Blue Book has included guidance regarding EV charging for some time, but things are changing which require extra attention.

“We found that the first EV chargers installed were mainly on the larger sites, such as motorway service areas run by major operators, and there was an understanding of the risks involved. EV chargers must be kept out of hazardous areas on filling stations as they risk public safety by potentially causing an explosion.”

Thompson says that within the Blue Book, there is clear guidance showing hazardous areas on the filling station, including distances from tanks, pumps, road tanker positions and vent pipes.

This states that the charger, the vehicle being charged, and the full extent of the charging cable must be outside the hazardous area. And the IET (Institute of Engineering and Technology/APEA guidance document states that reference to hazardous areas shall be deemed to include both permanent and temporary hazardous zones as defined in the Blue Book.

“The later developments are now proving more of a challenge, as EV chargers are being installed on smaller sites where it is often difficult to find a position outside the hazardous zones,” explains Thompson. “What appears to be a trend now is that marketing companies are approaching operators and leasing land on the filling station to install EV chargers without the operator having to pay for the equipment. They appear to be responsible for the installation but, in some cases, it has been found that they are installing them in unsatisfactory positions, causing public safety concerns.”

At present, the existing law does not recognise the installation of EV chargers as a “Material Change” to a petrol station that would require notification to the Petroleum Enforcing Authority (PEA). “My advice to operators is to check with your PEA if you are hoping to install this equipment. If it proves to be dangerous, a prohibition notice preventing their use could be issued,” says Thompson. Put simply, EV chargers placed inside hazardous areas are a risk to public safety.

Another cause for concern, according to Thompson are leak detection alarms.

“Since the 1990s, petrol station design and construction has included secondary containment with leak detection on tanks and underground lines, making stations much safer from environmental leaks and reducing fire and explosion risks.

“We are, however, finding that in some cases there is a lack of knowledge on site of what to do when alarms sound, and also a lack of maintenance of such equipment. One example involved a tank leak detector warning the operator that the tank was leaking. The staff, wanting to silence the noise, removed the detector to stop it. This was found on a routine safety inspection by the Petroleum Inspector.

“A more serious incident occurred when 14 double-wall tanks were installed at a motorway service station with the necessary leak detection systems. One of the managers heard the alarms and took no action other than to turn off the noise. When the Petroleum Inspector called and turned the alarms back on, 11 of the 14 tanks were found to be leaking. This was a clear case of a lack of training.

“Site operators have much to consider in running sites, marketing goods and managing crime prevention, and are often not experts in safety systems such as leak detection. My plea to the industry is to remind everyone that these systems should not be left to run unattended — they must be maintained.

“In this day and age, it is also possible to ensure that when alarms sound, warnings can be sent directly to a responsible person’s mobile phone or computer to make sure appropriate action is taken.”

Security issues

Thompson mentioned crime prevention, and Bruce Nichol, operations director at BOSS, advises that forecourt operators prioritise health and safety when addressing security issues due to the high-risk nature of the environment.

“Key considerations include the prevention of fuel theft, which not only causes financial loss but may also lead to dangerous driving behaviours such as erratic driving on the forecourt and confrontation with aggressive customers. Operators should implement CCTV systems, ensure clear visibility across the site, and provide adequate lighting to deter criminal activity and support law enforcement.”

Nichol says staff safety is paramount, especially during lone working or late-night shifts. Indeed the HSE says that as an employer, you must manage any health and safety risks before people can work alone.

“Panic alarms, secure payment booths and clear communication protocols enhance protection,” says Nichol.

“Training is essential to equip staff with the skills to handle aggressive or suspicious behaviour safely and to manage conflict without escalation.

“Vehicle and pedestrian segregation should be maintained to minimise risks during confrontations or emergency situations. Safe escape routes and unobstructed access for emergency services must be preserved at all times.”

Then there is cash handling to consider and Nichol recommends that any procedures are as discreet as possible, with regular banking and the use of drop safes to reduce on-site cash holdings. “Robbery or violent crime should be addressed through both physical deterrents (eg screens, bollards) and post-incident support such as counselling and incident reporting systems.”

BOSS partners with accredited training providers to deliver a range of specialist courses and risk assessments designed to ensure contractors can work safely on petrol station forecourts. These programmes cover essential topics such as hazardous materials handling, site-specific safety procedures and legal compliance.

“By completing approved training, contractors gain the knowledge and certification required to operate in high-risk environments confidently and responsibly. BOSS also supports forecourt operators by promoting best practice and ensuring all personnel are properly trained and assessed before starting work, helping to reduce incidents and maintain the highest standards of health and safety on site.

In-store responsibilities

When it comes to the convenience store side of the business, the rules and regulations are plentiful. From food hygiene to age-related sales, and from licensing to employees’ rights, they cover everything.

With more and more forecourt shops offering an increased food-to-go offer, this adds extra layers to the retailer’s responsibility including air and water compliance. This includes managing Legionella risks.

The ‘responsible person’ for Legionella compliance shoulders some heavy responsibilities,” says Martin Hembling, commercial director for Swiftclean.

“Specialist air and water services providers undertake their work in the knowledge that it comes with a legal requirement to complete it competently and compliantly; but this does not let the appointed ‘responsible person’ off the hook. You cannot entirely delegate legal responsibility for a particular area of compliance, either to a supplier or a colleague – you can only share it,” he explains.

“Your first legal duty is to appoint a specialist provider who will not only complete the work competently and compliantly, ensuring your compliance, but who will also clearly document their work. Robust records are vital for both air and water services, as the penalties for non-compliance can be severe.”

In the UK, as a landlord or the business owner, you are required by law to have an up-to-date Legionella risk assessment in place, to assess and control the risk of exposure to Legionella bacteria. Legal duties are set out in The L8 Approved Code of Practice, issued by the HSE. You must take the necessary measures to minimise your Legionella risk:

• identify and assess any potential sources of risk

• sufficiently manage the risks you have identified

• put in place appropriate preventative measures

• keep detailed and accurate records of any testing, results or work carried out.

“We strongly recommend that documentation includes before and after photography of any cleaning or remedial work; eg before and after images of a regular water tank clean.

If there’s a Legionella outbreak, the ‘responsible person’ and their organisation may be prosecuted for negligence. If found guilty, the organisation can face limitless fines, while the individual can face a custodial sentence; especially following a serious outbreak or fatality.

“Appoint a member of the Legionella Control Association (LCA) with a long track record of uninterrupted membership. Members can provide you with robust documentation and are themselves reassessed annually by the LCA,” says Hembling.

If you serve hot food, you will also need a ‘responsible person’ when it comes to fire prevention under the Regulatory Reform (Fire Safety) Order and the Workplace (Health, Safety & Welfare) Regulations.

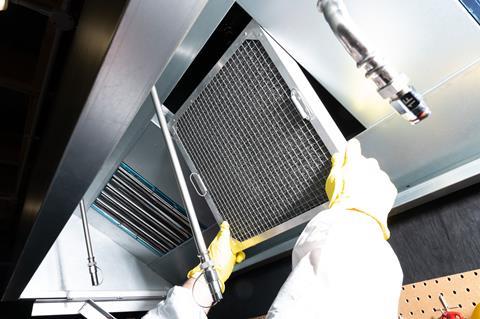

“Do not overlook the regular inspection and cleaning of the commercial kitchen grease extract system – including canopies, filters, ductwork, risers and fans – in compliance with TR19 Grease, the specification issued by the Building Engineering Services Association (BESA).

“Your buildings insurance provider will also expect compliance with TR19 Grease, and failure to comply can invalidate your policy. It can also have serious legal consequences, so evidence of compliance is vital to protect you from prosecution. Appoint a member of BESA’s Vent Hygiene Register, who will issue official certification of every clean, including before and after photography of each individual asset.”

Health and safety rules and regulations are in place to protect us all. To protect your staff, your customers and your business, regular risk assessments will help you to maintain compliance and have a certain amount of peace of mind.

- To help forecourt operators navigate through the various regulations they must adhere to, cloud-based management solutions company Cegid has produced a report which is free to download, and it says turns “compliance complexity into competitive advantage”. Visit: https://forecourttrader.co.uk/whitepapers/compliance-can-supercharge-forecourt-businesses/706167.article